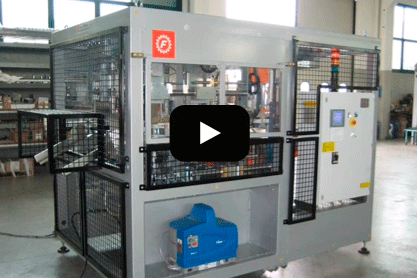

Automatic tray erector FO-AM-H2/8

View the embedded image gallery online at:

https://www.officinafreddi.it/en/products-standard/tray-erectors/105-automatic-tray-erector-fo-am-h2-8.html?tmpl=component&print=1&layout=default&page=#sigProGalleriacd7fe80be1

https://www.officinafreddi.it/en/products-standard/tray-erectors/105-automatic-tray-erector-fo-am-h2-8.html?tmpl=component&print=1&layout=default&page=#sigProGalleriacd7fe80be1

The machine is able to mould trays (by hot-melt closure) obtained by matched cardboards blanks.

The following technical features enable the machine to answer to the various requirements concerning the packaging market:

- Very fast and easy change size without wrenches and without replacement of parts.

- Possibility (on request) to mould trays having different angle closure kinds, for example:

- 90° corners closure.

- Bevelled external limb overlay (bevels having different angles).

- Round angles (very useful for bottles locking and stability).

- Possibility to manufacture mixed kinds of closures: for ex. nr. 2 round corners and nr. 2 bevelled corners).

- Possibility to feed manually the blanks to the dynamic blanks magazine during the machine running. This opportunity provides an output continuity.

- On request, the machine is equipped with a trays outlet conveyor.

- A 180° tray turner unit can be installed on the outlet conveyor. The unit is necessary when the palletizing line needs trays and turned trays.

- On the outlet conveyor there is the possibility to install a tray centring device at the gripping point.

Productive characteristics:

Matched cardboard blank sheet.

Dimensions of erected trays:

MAX: 640x840x150H mm.

MIN: 360x560x80H mm.

Closure with N. 2 hot melt strips for each corner

Machine’s output: 8 tray/minute

Technical data:

Installed power: 7 kW

Compressed air consuption: 180 Nl/minute at 6 bar